|

|

|

AirBurst® is a revolutionary technology that uses compressed air to dislodge debris caused by mineral buildup.

This demonstration was completed by AirBurst ® Technologies, LLC

It took LESS THAN ONE MINUTE! |

|

The Power of AirBurst®

AirBurst® can be used to rehabilitate and develop a variety of well types:

- Municipal

- Commercial

- Industrial

- Injection

|

- Irrigation

- Injection

- Recover

- ASR

- Residential

|

Back to top

|

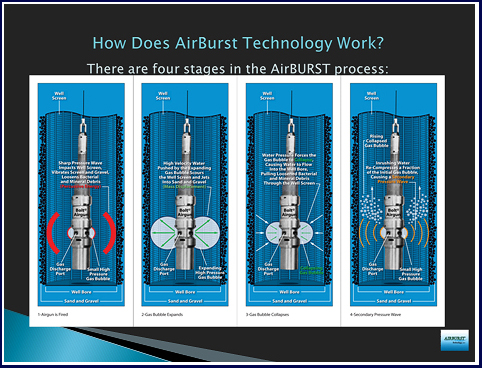

There are four stages in the AirBURST® process:

The Four Steps Explained:

-

An Intense vibration is created to breakup the concentration of minerals.

-

The rapidly expanding air bubble creates an energy source in the form of a pressure wave that surges water against/through the screen.

-

When the bubble collapses the negative pressure that is created dislodges material into the well bore and is expelled.

-

A smaller bubble is formed to create another, less intense pressure wave.

Back to top

What Exactly Will AirBurst Do?

|

|

-

Break Up Mineral Cementation of Gravel Pack and Formation

-

Remove Silt and Fine Sand from Pack, Formation, and Fractures in Rock Wells

-

Scour Bio-Slime from Screen, Gravel Pack, and Formation

-

Enlarge and Extend Fractures in Rock

|

|

Reasons to Use AirBurst

|

| |

1. Efficient |

-

Short setup time; decreases down time

-

Fast removal of debris upon initial startup

-

May be used on shallow applications

-

Reaches beyond well bore; recorded > 75’, limestone well

|

|

|

2. Cost Effective |

- No special permits required

- Reduces labor and equipment costs

- No deterioration of casing or screen, unlike acids

- No hazardous chemical, transportation, or disposal costs. No liability cost due to chemical usage.

|

|

Back to top

|

Home | About Us / History | About Our Services | Well Drilling

Geothermal Wells | Airburst Technology | Contact Us

Thompson Well & Pump, Inc.

ST. LIC # 7157

DeLand Ph. 386-740-0180

Orlando Ph. 407-619-2523

© 2008 Thompson Well & Pump, Inc. |

|

|